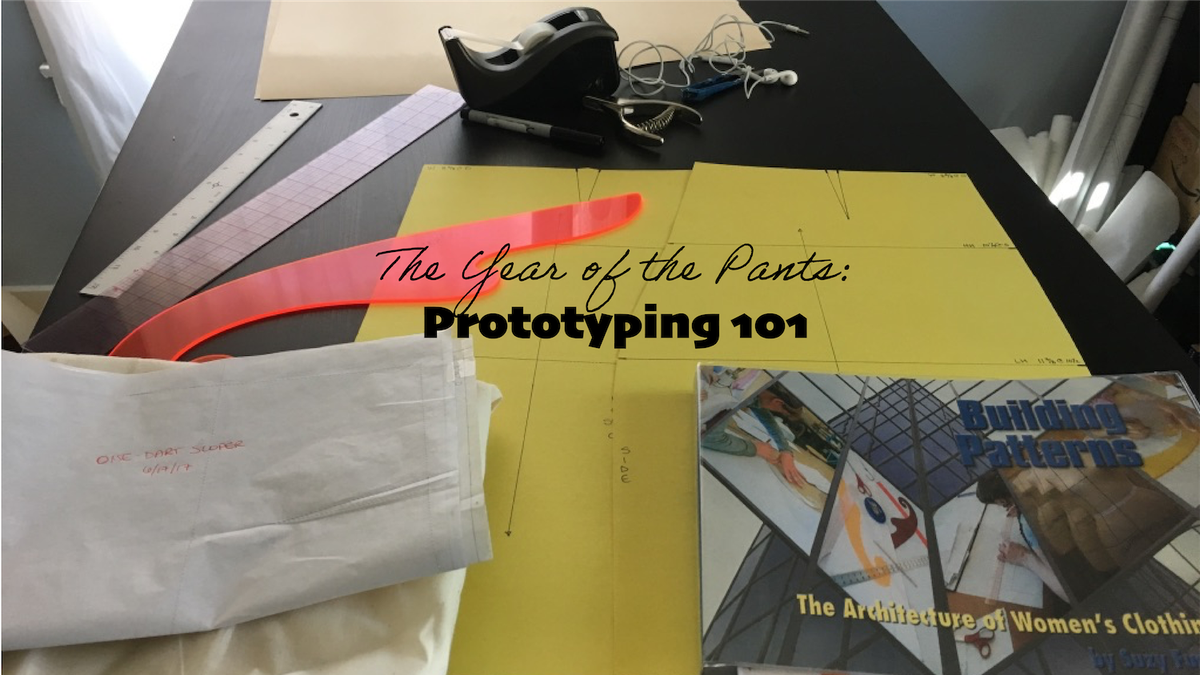

Prototyping 101

This post is part of a series called 2020: The Year of the Pants. Catch all of the posts via the YOTP tag.

Apparel prototyping is a lot like software prototyping, with one major difference: where software is a whole bunch of zeroes and ones, apparel exists in a physical space, made from a variety of materials, and results in non-zero waste beyond time. Whereas creating software is like alchemy, creating apparel is arts and crafts taken to a whole new (and often industrial) level. Money isn't just time, it's also materials, vendors, shipping, packaging, retail space, and more.

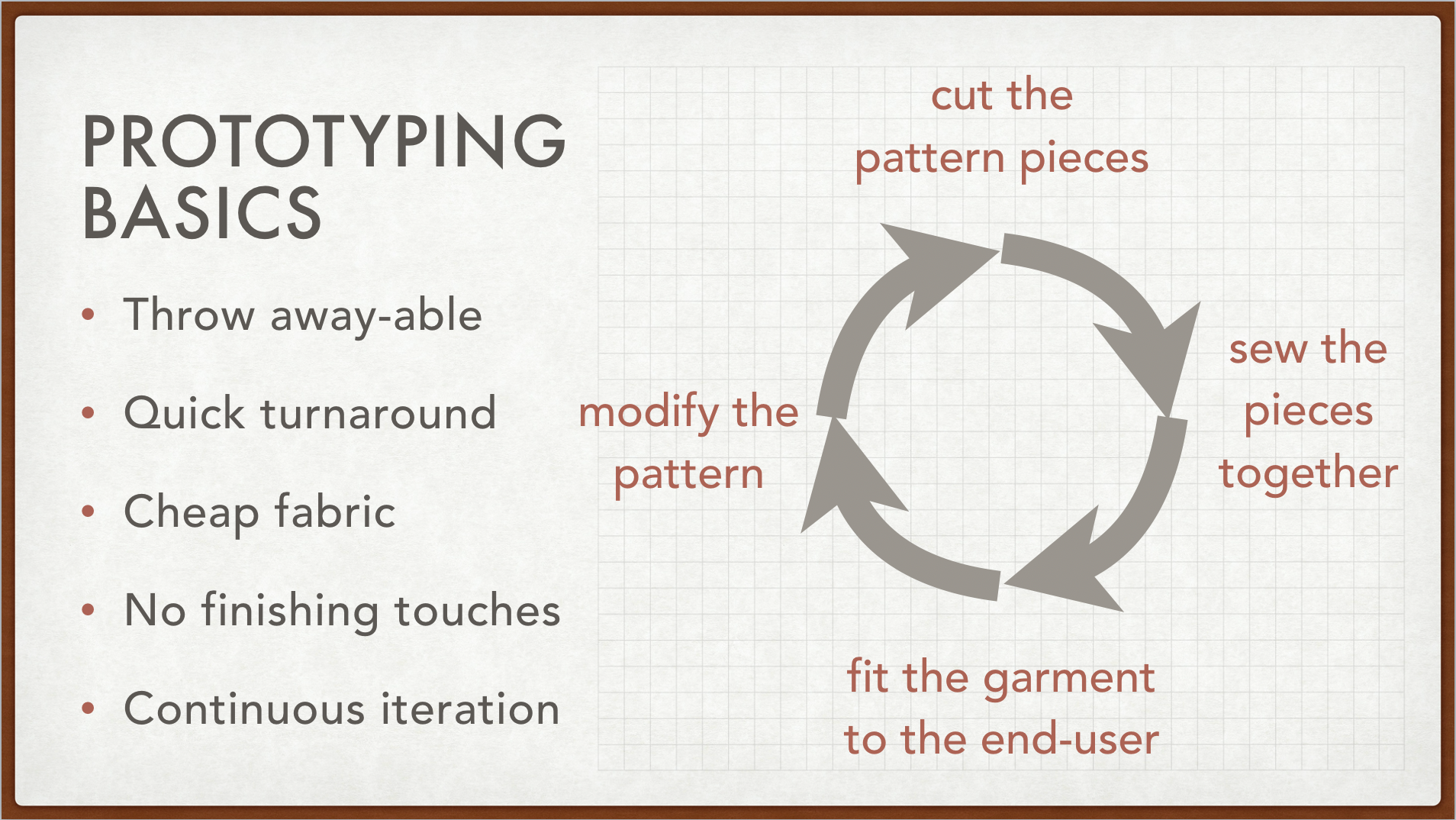

The key piece here is that prototyping is about the quick turnaround, defying perfection, and focusing on learning as much as possible as cheaply as possible.

There are a few different types of prototypes in apparel:

- The proof of concept/muslin. This is usually made out of super basic, cotton material. It has no color and no stretch. Its main benefit is that it's cheap and plentiful. It's good for getting basic styling details figured out, and general fit. It doesn't make any sense to make this version perfect, because all fabric behaves differently. If you have some deadstock[1] fabric sitting around and are confident in your overall fit/shape, you might opt to completely skip this stage and go straight to #2.

- The fit sample/wearable muslin. Ideally, you'd have the exact fabric you will be making the final garment out of. If not, you'd have a fabric that behaves very similarly to your final fabric. This sample has all the design details and is helpful for understanding the true fit of the garment, so that you can go back and clean up any fit changes needed.

- The costing sample. In the apparel industry, this would be a prototype that has all the bells and whistles of your design, so that you can understand how it's constructed (and thus how much it would cost to make). In home sewing, this might be the first make of a series made from a "TNT" (tried and true) pattern. After costing, you might realize the original design is too expensive and that the design needs to change to cut costs.

Each of these prototypes is another layer of iteration, and each layer might have its own series of iterations.

In software, testing is a huge part of writing good code. If we think about the pattern as our algorithm, the human is the test suite. In apparel, we check our alogirthm against our test suite so that we can ensure that we're meeting all the criteria of a good piece of clothing.

An aside: Society all too often wants people to believe that when clothes don't fit, it's the body that's broken. But I'm here to tell you that in apparel, we do TDD (aka Test-Driven Development), and the tests are always perfect. Your body is never too fat, too skinny, too tall, too short, or any of that other nonsense. When clothes don't fit, it's because the algorithm is broken! THE CLOTHES ARE WRONG AND THEY SHOULD FEEL WRONG. You, my friend, are perfect, just the way you are right now.

As we iterate on the design and compare it against our tests, we quickly come to a consensus on the final product. And then, like a boss, we can walk around in our clothing with glee! (Or send it off to a factory to be produced en-masse... but that's an article for another time 😉)

Coming up next, I'll actually have some pictures to share!

In the meantime: what's your process?

Footnotes

[1] Deadstock refers to fabric that has already been made/purchased. From a sustainability perspective, the cost to the planet has already been made, so using it is far better than putting it in the landfill and creating new fabric from scratch. I'll write a post on this if it's of interest to folks.

Banner photo: the first skirt that I drafted and sewed to my own measurements. I wear it with pride!